ELECTRIC SYSTEM

Electric system adopts the advanced CAN-BUS control technique. It realized all the process control and monitoring of the engine, pump, valves and working actuators. It ensure the high reliability and intelligence. The key components are from international brands.

Optimum Match-power Technology

The energy-efficient control of closed look feedback is used. While operating, control system automatically regulates hydraulic pump power according to load need and makes engine output optimally match with pump power.

Human-Machine Interaction Environment

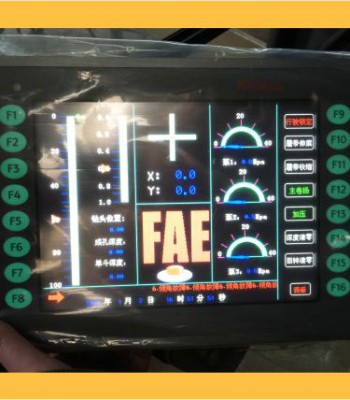

The colorful 10.4-inch display pane, especially designed for the machine, monitors all the working data at real time and also automatically diagnoses on failure. The working parameter is conveniently set in HMI environment.

Mast Control Technology

The mast obliquity is monitored continuously and it operated by 3 ways : manual control, automatic control and manual control with automatic compensation. on the premise of safety, it mostly reduces the driver’s labor intensity and improves operation efficiency.

Depth Measurement Technology

It is by one-key automatic adjustment that depth coefficient is recalibrated. It is convenient and effective to compensate pulley wear and other mechanical error.