Brief Intoduction

EQUIPILE brand of Hydraulic Static Pile Driver, features with no noise, no vibration, no polution, high piling efficiency & excellent quality (The normal construction conditions, 500-1000m per 8 hours), it has wide application in jacking in concrete spun pile, square pile, H pile, and other precast piles at the site of:

- Clay, soft soil, sand layer, etc

- Noise regulated urban area.

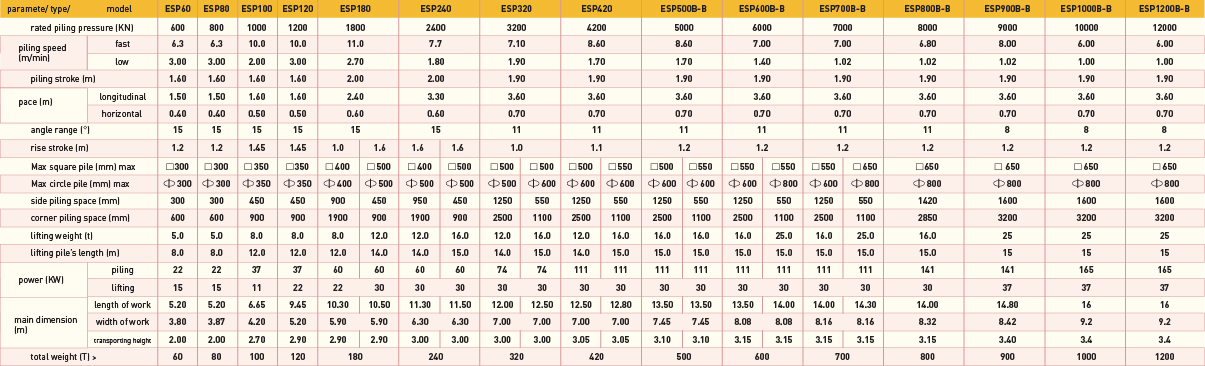

- Vibration regulated areas, such as near old buildings, precision instrument buildings, subway, overpass and so on. ESP series of the HSPD ranges from 60 to 1200 tons that can diferrent foundation conditions and customers; meanwhile, we can provide special design for customer’s requirement.

According to the way of pile driving we offer the following three models of pile drivers for each tonnage at the customer’s choice:

According to the way of pile driving we offer the following three models of pile drivers for each tonnage at the customer’s choice:

- Embracing pile drivers

- Top-pressing pile drivers

- Embracing and top-pressing pile drivers

Execellent in Design

Our products possess the following technical advantages over those of the same kind being made at home and abroad.

Efficiency:

To ensure the high working efficiency of the whole machine, we use hydraulic systems with big power and great flow, the pile driving mechanism with multi-speed control and being quick in getting ready for operation.

Product Introduction

A Great Choice of Product

We are able to produce nearly 40 ESP of Static Pile Drivers from 60 tons to 1200 tons at the customer’s own choice, or make a new model according to the customer’s requirements.

Each tonnage is classified into the following three models :

- With the function of side piling and corner piling.

- Without the function of side piling and corner piling.

- With a connecting system for adding Side piling and/or corner piling Mechanism if Necessary.

Each model of pile drivers can work with a variety of piles, square piles, thick-walled round piles, thin-walled round piles or other of stell piles with different mechanism to hold piles.

Three types of side piling mechanism give more practically and availabilty for customers which also can solve many practical problems, for example: it is much close to the wall for side piling with attachable side piling mechanism or inserted side piling mechanism, and it can reduce the weight and length for main body during transportation:

- Fixed side piling mechanism

- Attachable side piling mechanism

- Inserted side piling mechanism

High Reliabilty:

To ensure the high reliabilty of our products which engineering machines should possess, we improve the design and use very reliable materials or components which we select carefully in the process of purchasing. We won a number of patents by improving the practicality: for example we used inverted cylinder as a supporting leg has become a patent so as to avoid the easy breakage of cylinder which was the case of traditional design Attachable side piling mechanism and retracable legs are new patents of us that can save much cost and increase working efficiency for customers.

Especially the design for retractable legs as a important patent can save much cost for customers during transhipment.

Since we have constantly improved our design of pile drivers for more than 10 years, every part of the machines is easy to be taken apart, which provides convenience in transportation and maintenance.

Main Technical Specifications of HSPD

Note: The below value is for reference only. Factory reserves the right to make changes in he published specifications without prior notices.

Another good example is that we use the 16 cylinders clamping mechanism with multi-touching points to achieve even clamping force to protect round piles from damage so that embracing pile drivers will be able to take place of top-pressing ones.